This is a cheaper desktop ASCEN PCBA circuit board three-proof conformal coating machine that equipped 3 axis,it is a single station selective coating machine and has a high cost performance.ASCEN conformal coating machine can choose the different glue supply system according to the glue packaging, and choose different configurations for different glues.this PCB selective conformal coating equipment suitable for three-proof paint,acrylic,polyurethane,silicone,UV glue,ink and so on.

PCB coating Application:

• Resist moisture and pollution (and electricity leakage);

• Resist salt spray and mold;

• Resist corrosion (such as alkali) and improve the anti-dissolution or wear capacity;

• Raise the lead-free welded spot's anti-fatigue strength;

• Inhibit arc and halo electricity discharge;

• Reduce the mechanical vibration and impact;

• Resist the high temperature and release the stress resulting from temperature change

Features

1.Desktop PCBA conformal coating equipment equipped the hand-held teaching programmer supports English interfaces, which is simple and easy to learn. It is equipped with special personnel to guide and use. It can be basically mastered in about 30 minutes;

2. The PCBA conformal coating system can store hundreds of processing files, and each file can support 8000 instructions. It can be called out when in use. It supports DXF and PLT file import and automatic path optimization;

3. High end brand configuration, stepping motor system, Taiwan Shangyin guide rail, Japan Omron photoelectric switch;

4. According to different requirements, the coating speed / glue amount / coating track (space point, line, arc, etc.) can be set separately;

5. ASCEN PCBA conformal coating system customized small atomization valve as standard. The stable air pressure system maintains the consistency of glue output and can more accurately and effectively control the edge definition;

6.The whole plate plus heavy platform bottom plate ensures the perpendicularity of XYZ axis. The machine plus sheet metal structure is solid, beautiful, high precision and guaranteed quality;

7. Supply device: composed of glue storage barrel and stainless steel cleaning barrel The pressure barrel is composed of air conditioner, safety valve, vent valve, discharge port and inner barrel (pneumatic stirring type can be selected. The pneumatic motor of the pressure barrel can stir by itself to keep the paint in the barrel uniform. In the spraying operation, there will be no color difference due to paint precipitation);

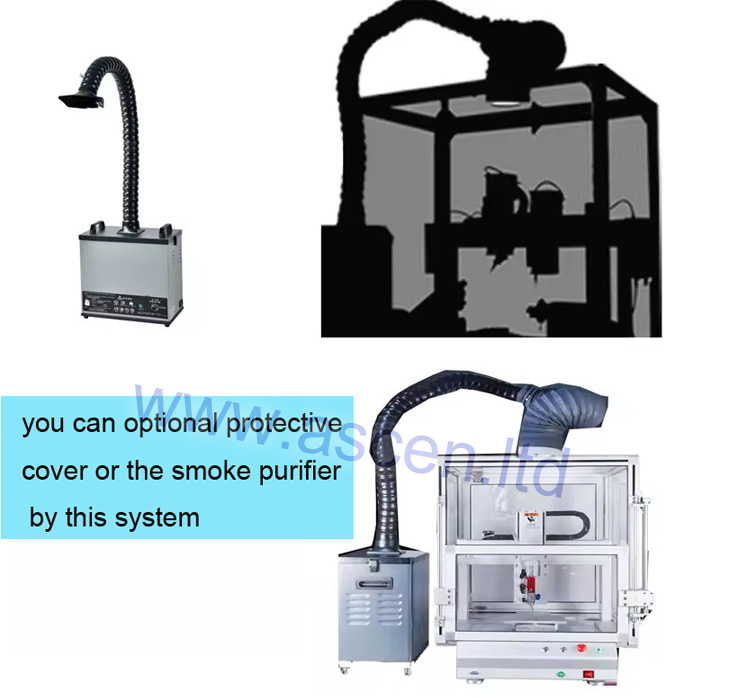

8. Optional cover with air extraction device: an air outlet is reserved at the top;

9. Lighting detection part: the equipment is equipped with LED lighting system and its own leduv detection light source, which can be converted through the change-over switch. The ultraviolet light source is used to detect the coating of three anti paint on PCB board, which is convenient and practical;

10. The ASCEN single station selective conformal coating equipment can optional equipped with automatic cleaning function. When the equipment is shut down, it is switched to the cleaning mode through the installation and replacement switch. The cleaning liquid in the pressure bucket of cleaning liquid will be pressed into the spray gun through the pressure bucket to complete automatic cleaning without manual disassembly and cleaning of the spray valve.

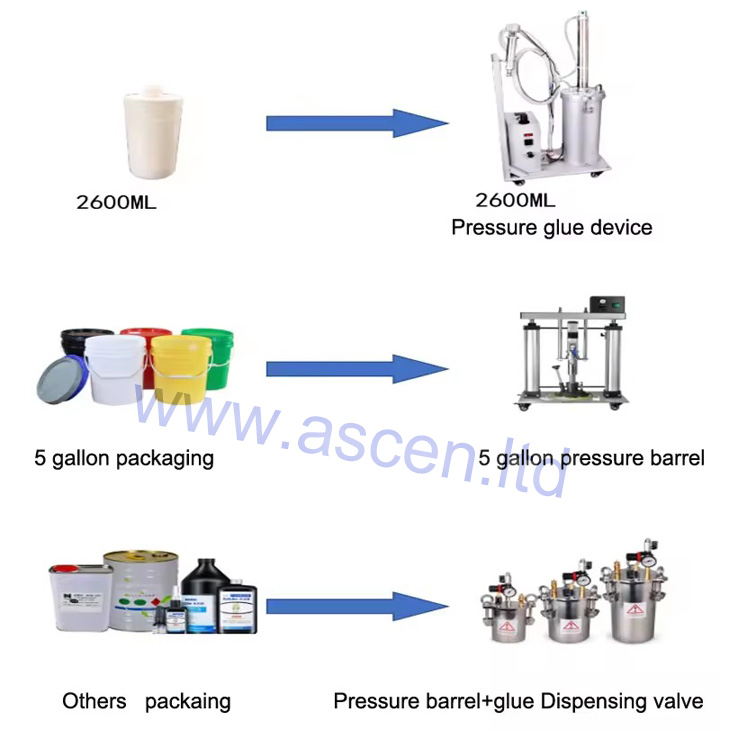

11. Choose the different glue supply system according to the glue packaging, and choose different configurations for different glues.this PCB selective conformal coating equipment suitable for three-proof paint,acrylic,polyurethane,silicone,UV glue,ink and so on.