Application:

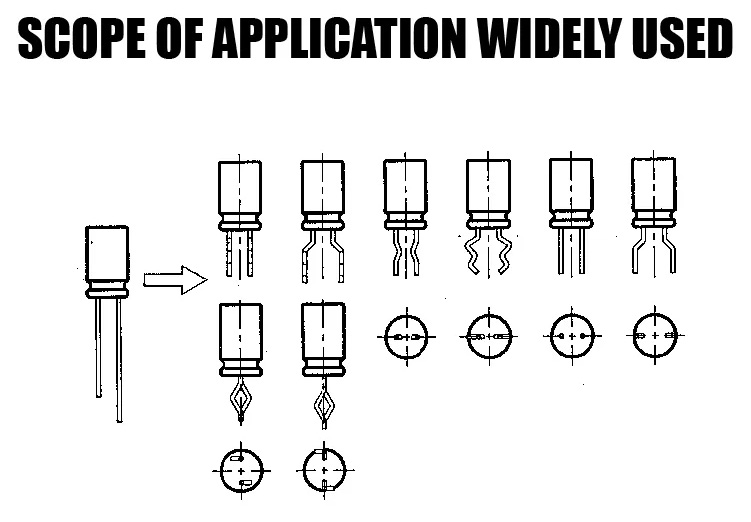

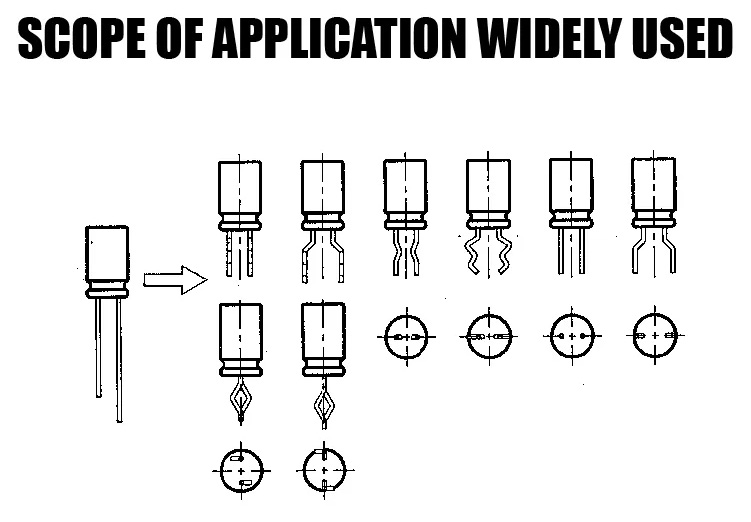

ASCEN Diode LED element forming machine apply to LED/light emitting diode,triode,aluminum electrolytic capacitor,metallic film capacitor,safety capacitor,quartz crystal and other upright type elements,which packed by in bulk or tape type.

Features:

1.High productivity auto forming and cutting in one time,Automatic feeding,cutter,forming,automatic discharging can complete all actions once,Speed control of the non-phase fine adjustment of transducer.

2. Import CAM mechanical transmission,precise stable,durable and low noise. Each part has the special hard coating with long service life.

3. The whole set of system is used PLC control with ultra strong stability.easy to lean and the data alignment is more convenient.

4. Speed control of the non-phase fine adjustment of transducer.

5. Upper clipand open clip system are rack and pinion type.The change of fixture centerline is invariant,no harm by clipping and more convenient to change the specification.(D4--(D6are shared the same fixture and(D8-(D10are shared the same fixture.

6. Molding pitch:2.0mm,2.5mm,5mm,7.50mm,10mm,15mm,20mm,25mm

7.Molding/feet cut method:odd leg,90℃bending, incurvature, excurvation and vertical angle,etc.

8. Length of feet cut:2.5mm-28mm.

9. Working pressure:4kg/Cm2

10.The special molding pattern can be customized according to the clients different requirements.

11. The bulk elements forming equipment is anti-static.

ASCEN radial element forming machine has the wide applicability,mould and pallet with different dimensions can be made based on their differences

Molding pitch:2.0mm,2.5mm,5mm,7.5mm,10mm,15mm,20mm,25mm

molding/feet cut method:odd leg,90 degree bending,incurvature,excurvation and vertical angle,etc. the special molding pattern can be customized according to the clients different requirements