The 3M N95 cup mask making machine is the hot pressing forming machine and also named cup mask forming machine,it use the hot pressing principle of high temperature to produce the shaping part of N95 respirator cup mask.

The 3M N95 cup mask making machine is the hot pressing forming machine and also named cup mask forming machine,it use the hot pressing principle of high temperature to produce the shaping part of cup mask.This N95 Respirator cup mask making machine is composed of feeding frame,mold,cutting and material clamping, etc., controlled by PLC, to achieve the formation of cup masks.

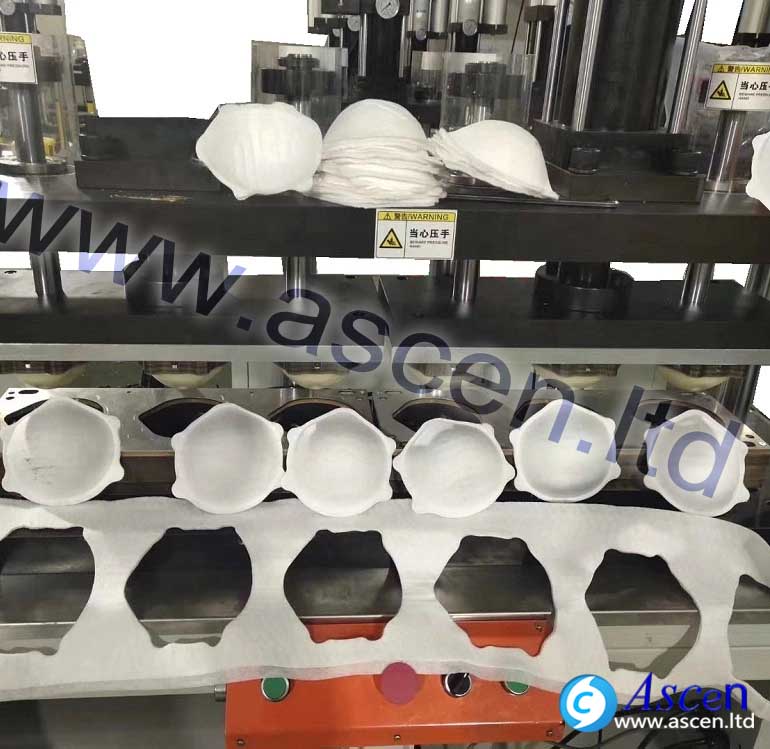

ASCEN N95 cup style mask making forming machine adopts PLC control system,man-machine interface touch screen display,fully display the humanized operation concept;Can form a standard mask one to four layers at a time,fast to finalize the design;The traditional mold sticking problem is solved by unique technology.At the same time can output five pieces of cup mask,if the cup mask making machine customized to two groups,the Max. Can output total of 10 pieces of cup mask at one times, high efficiency.

Functions :

1.Adopting Mitsubishi PLC control system, stable performance.

2.Using high quality cylinder and special aluminum alloy die, forming three layers, four layers mask by hot pressure. The products are firmly and uniform size after forming, doesn't destroy material.

3.Reasonable high quality aluminum structure, solid and durable.

A whole cup mask production line include the above 3M N95 Cup mask making machine machine,also need the following cup mask after process making machine,different style cup mask need choose different type cup mask processing making machine.

Technical parameters:

1.Product name: Cup mask making forming machine

2.Voltage: 220V/50Hz

4.Power: 10KW

5.Weight: 520KG

6.Machine size: 1200(L)*1100(W)*1850(H)MM

7.Air pressure: 4-7 KG

8.Efficiency: 25-35pcs/min