Auto KF94 fish mask making machine aslo know as fish shaped folding mask making machine,it is an all-in-one machine of automatic three-dimensional medical folding mask.From the feeding of cloth to the completion of automation of finished products, including material feeding system,auto nose clip insertion,waste recovery and shape forming processing,folding forming processing,fish folding mask automatic welding and cutting process and finished product output,the automatic production on a machine is fully realized.The medical folding mask making equipment is feed by servo,the whole KF94 fish mask production line with the high durability and high speed,it can keep work long hours without any fault and output 80-100Pcs per minute.the special positioning system is perfectly matched with each production station,and the folding mask is produced with high quality.In order to meet the market demand,the mold can be adjusted according to the product,produced a variety of folding masks the whole fish style folding mask production line is fully automated vertion without any manual operation.

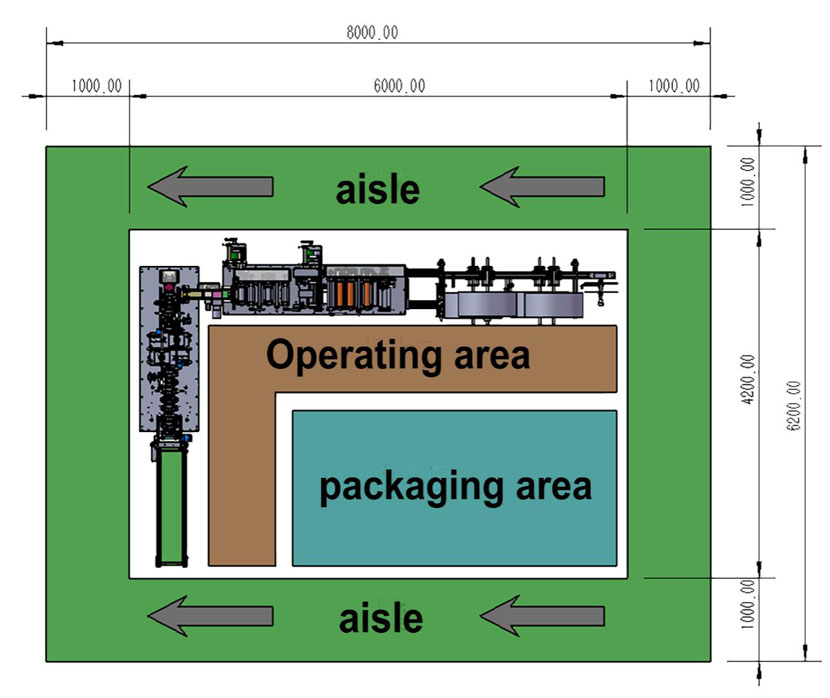

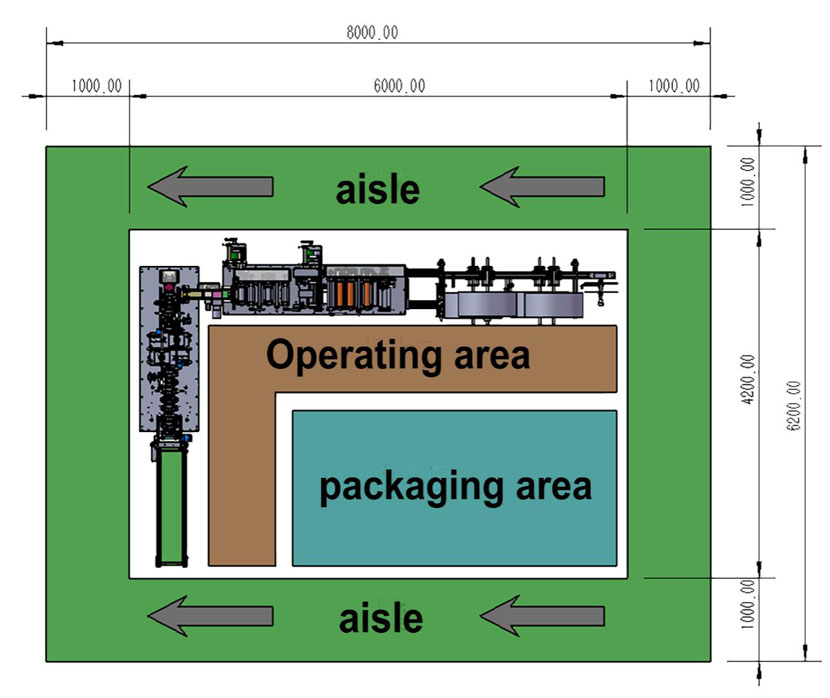

Fish folding mask making machine Operating area:

It is recommended that the single folding mask making machine operation area be 50㎡, which can be divided into aisle, machine occupied area, operation area and packing area according to the function (as shown in the figure below). When conditions permit, a 1 meter wide aisle should be reserved around the machine as much as possible to facilitate machine repair, commissioning and maintenance.

Fish shaped folded mask making machine features:

Fish shaped folded mask making machine features:

1.The whole fish shape folding mask manufacturing equipment is composed of the material rack part, the upper nose line part, the shape welding part, the folding forming, the shape cutter part, the turning part, the material dividing part, the ear strap part and the collecting part. The servo motor and ultrasonic welding technology are used to complete the production .

2.. Material rack: air expansion shaft, magnetic powder brake and controller to ensure that the material tension is moderate and not wrinkled;

3. The upper nose line part: the cylinder is welded with ultrasonic waves, and the nose line with the required length is fixed on the material;

4. The shape welding part: the mold is matched with ultrasonic wave, and the initial texture welding;

5. Folding: folding fabric;

6.Shape cutter part: custom-made cutter, roll-cutting and forming, at this time the mask is initially formed;

7. Flip part: turn the mask over to prepare for ear straps;

8.Partitioning: Reasonable distribution and increased production capacity;

9.Ear strap part: a special rotating disk for the mask machine industry, and the ear strap wire is spot welded to the semi-finished mask with ultrasound, and the mask is formed at this time;

10.Collection part: take out the belt, product collection;

The KF94 fish type folding mask making machine produce the standard folding mask sample as the following:

Click here fish shaped folding mask making machine fully auto production line,you can see the video showing the full automatic folding mask making machine production line how to manufacturing the KF94 fish type medical mask. If you want to know the budget to build the folded face mask making line, Please inquiry our ASCEN engineer team.

Click here fish shaped folding mask making machine fully auto production line,you can see the video showing the full automatic folding mask making machine production line how to manufacturing the KF94 fish type medical mask. If you want to know the budget to build the folded face mask making line, Please inquiry our ASCEN engineer team.

If you want produce the headband style head mounted KF94 fish shaped mask,please check the following sample,and click here add this folding mask stapling machine for assembly the headband loop.

If you want produce the headband style head mounted KF94 fish shaped mask,please check the following sample,and click here add this folding mask stapling machine for assembly the headband loop.

If your fish style folding mask with the valve,please click here add this ultrasonic welding machine for welding the breathe valve.